Programmer

ISP

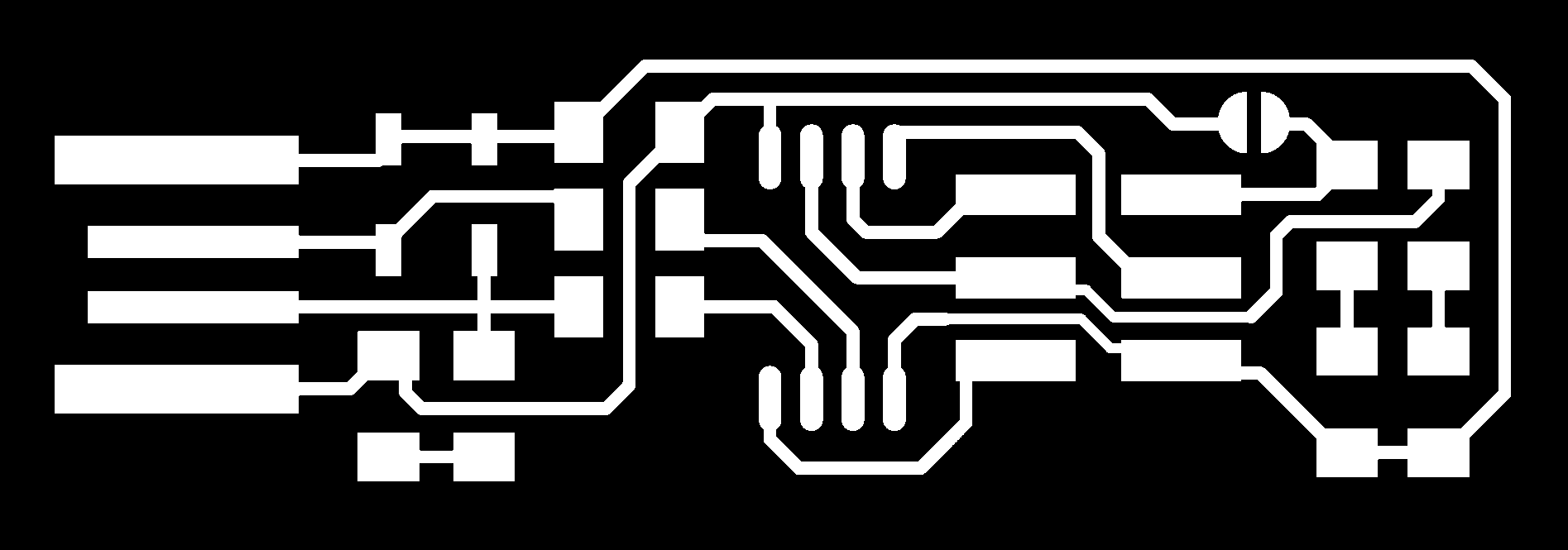

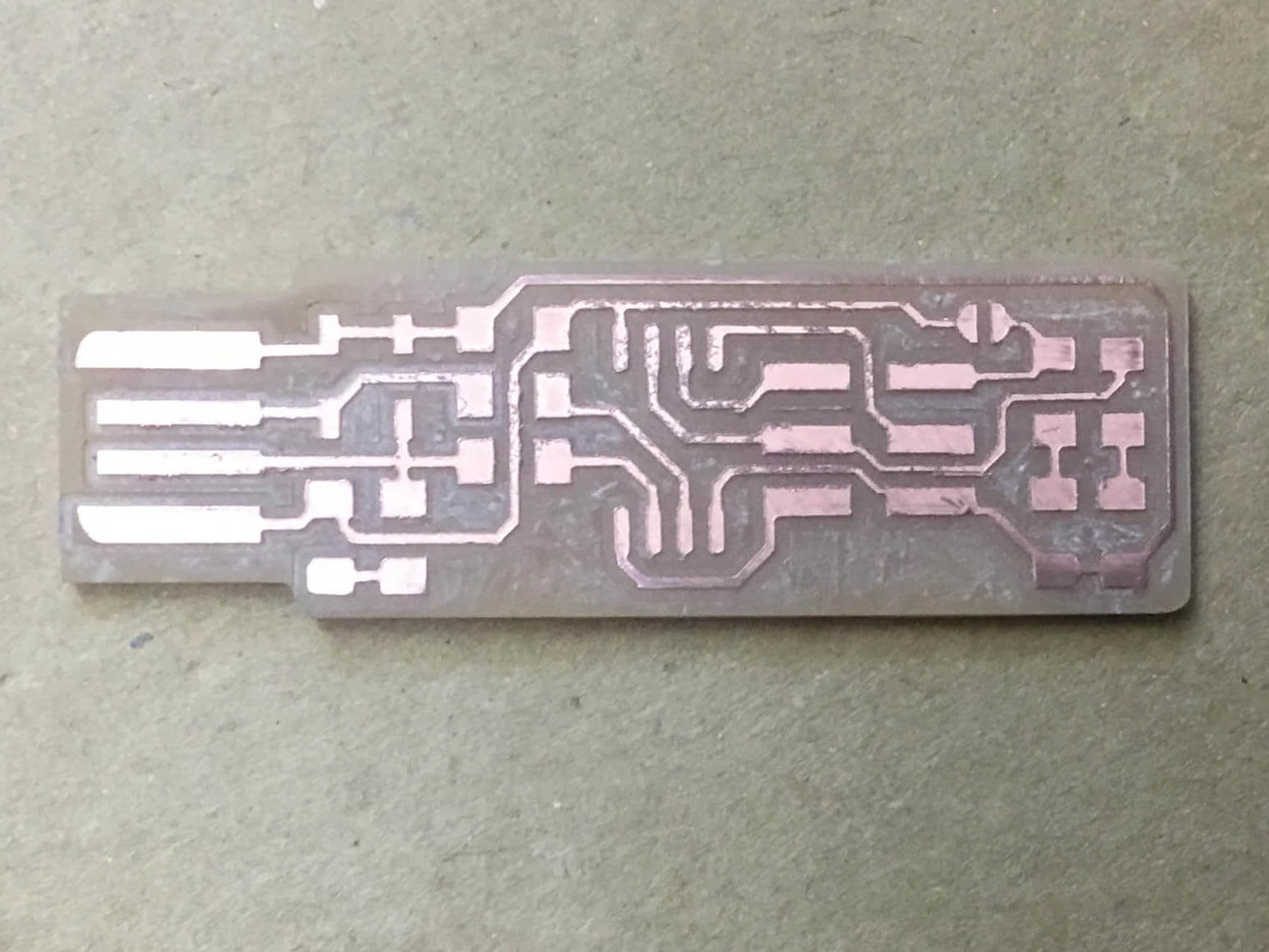

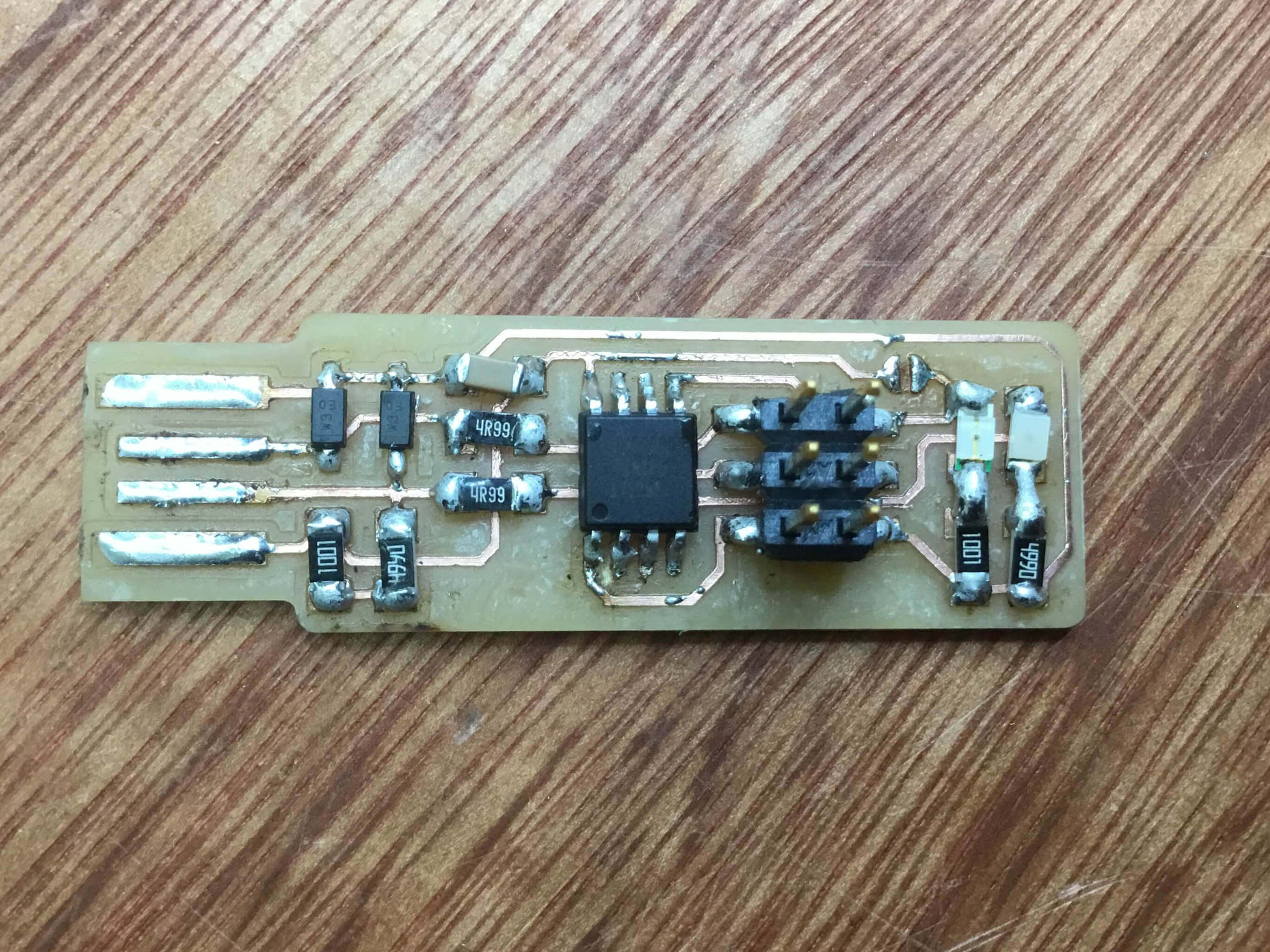

These are constituted with the Traces:

And an Interior cut out:

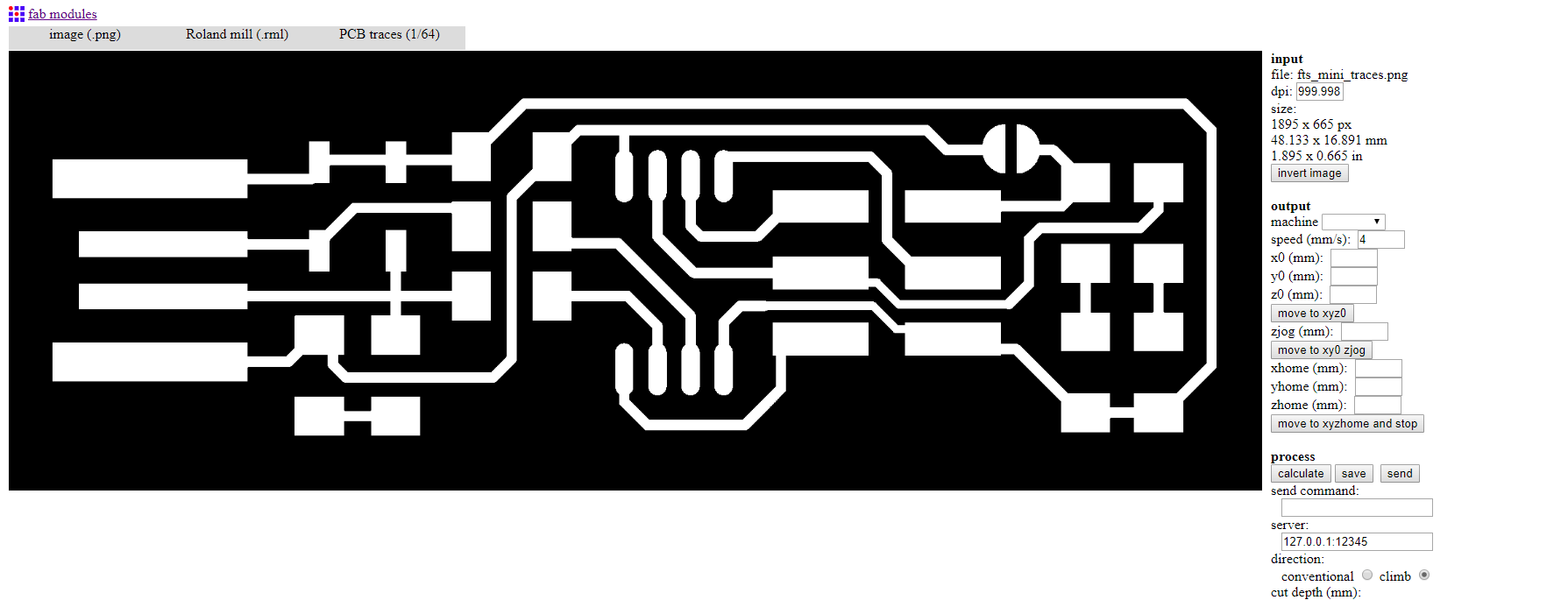

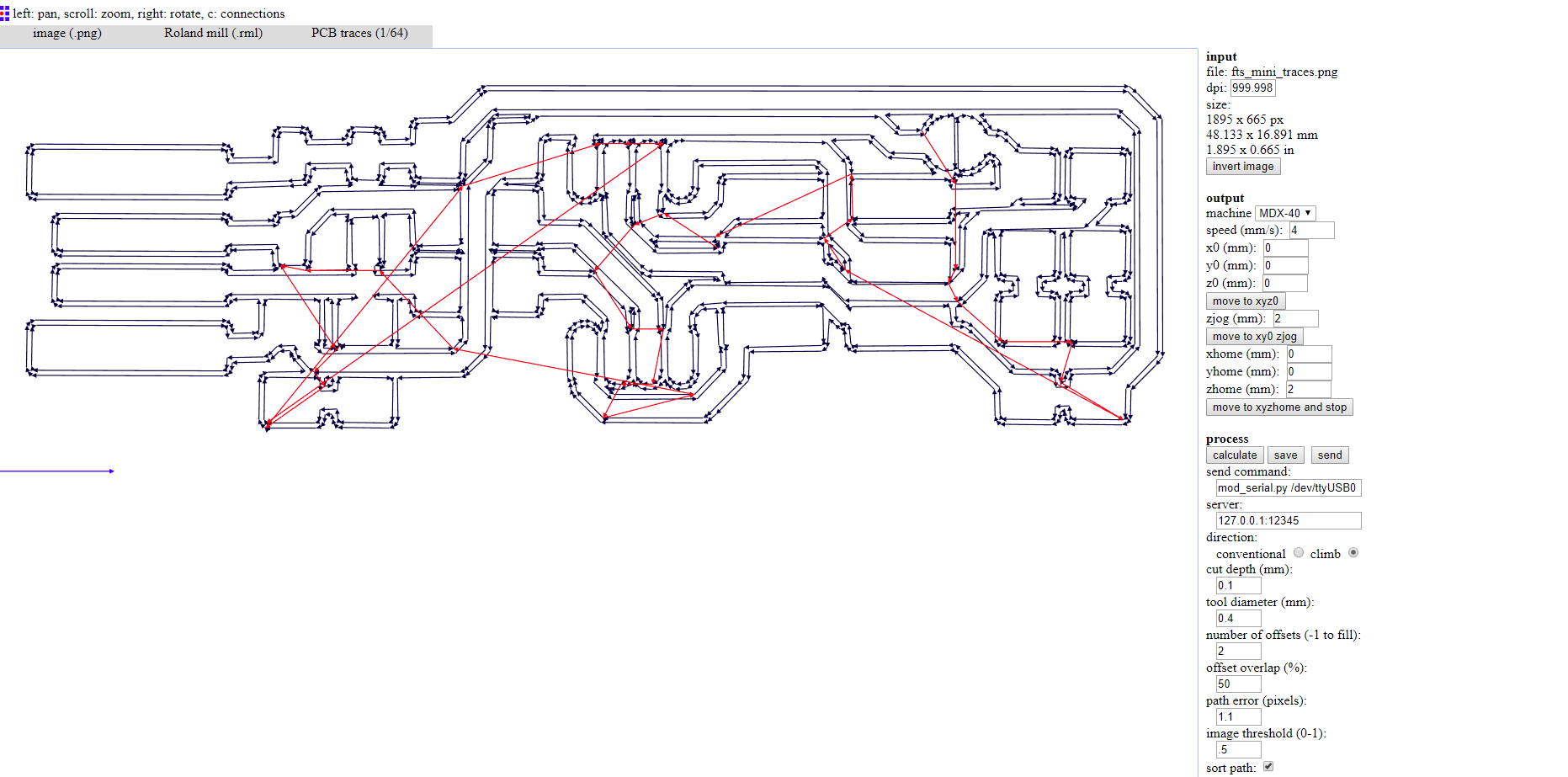

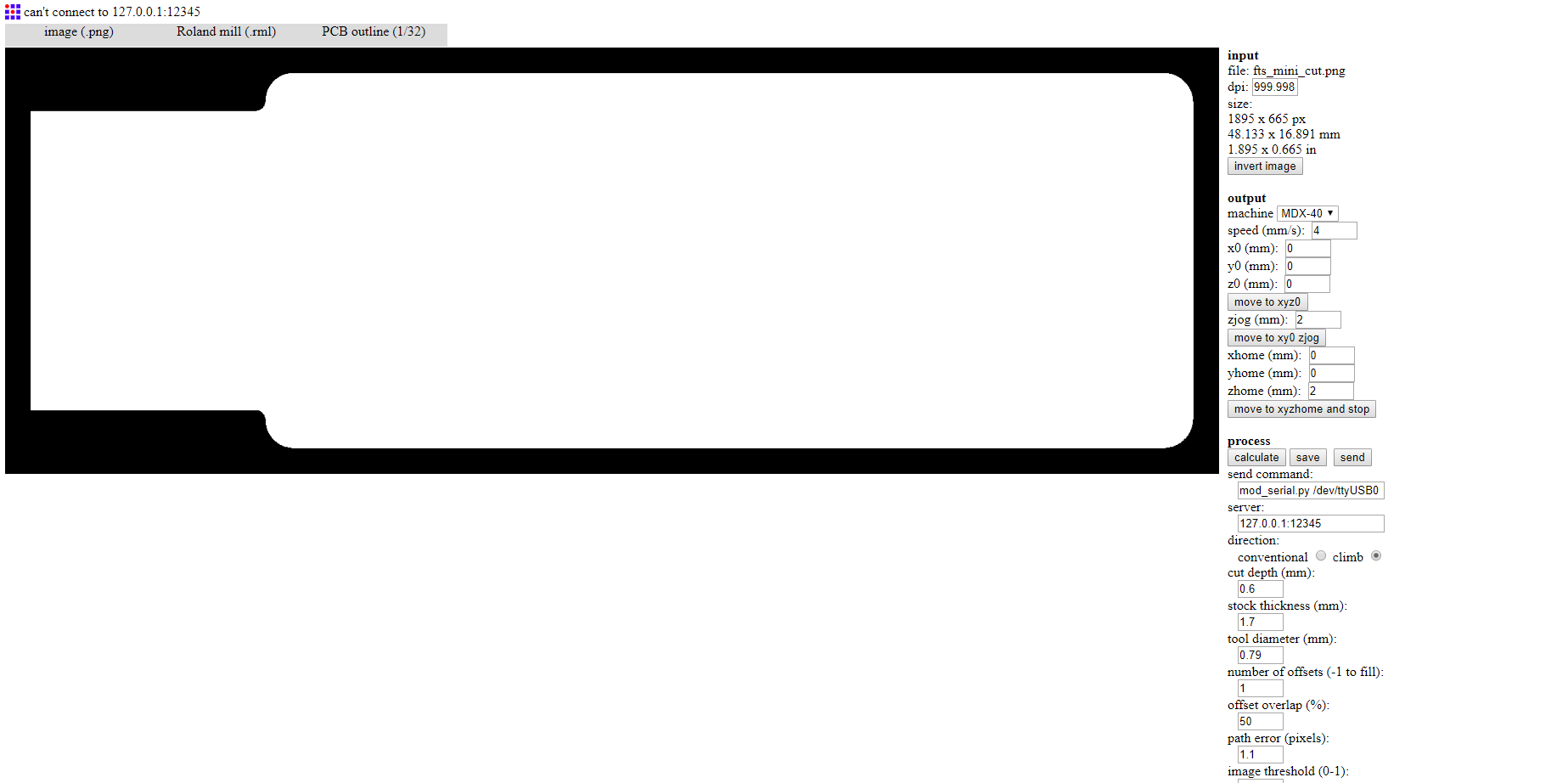

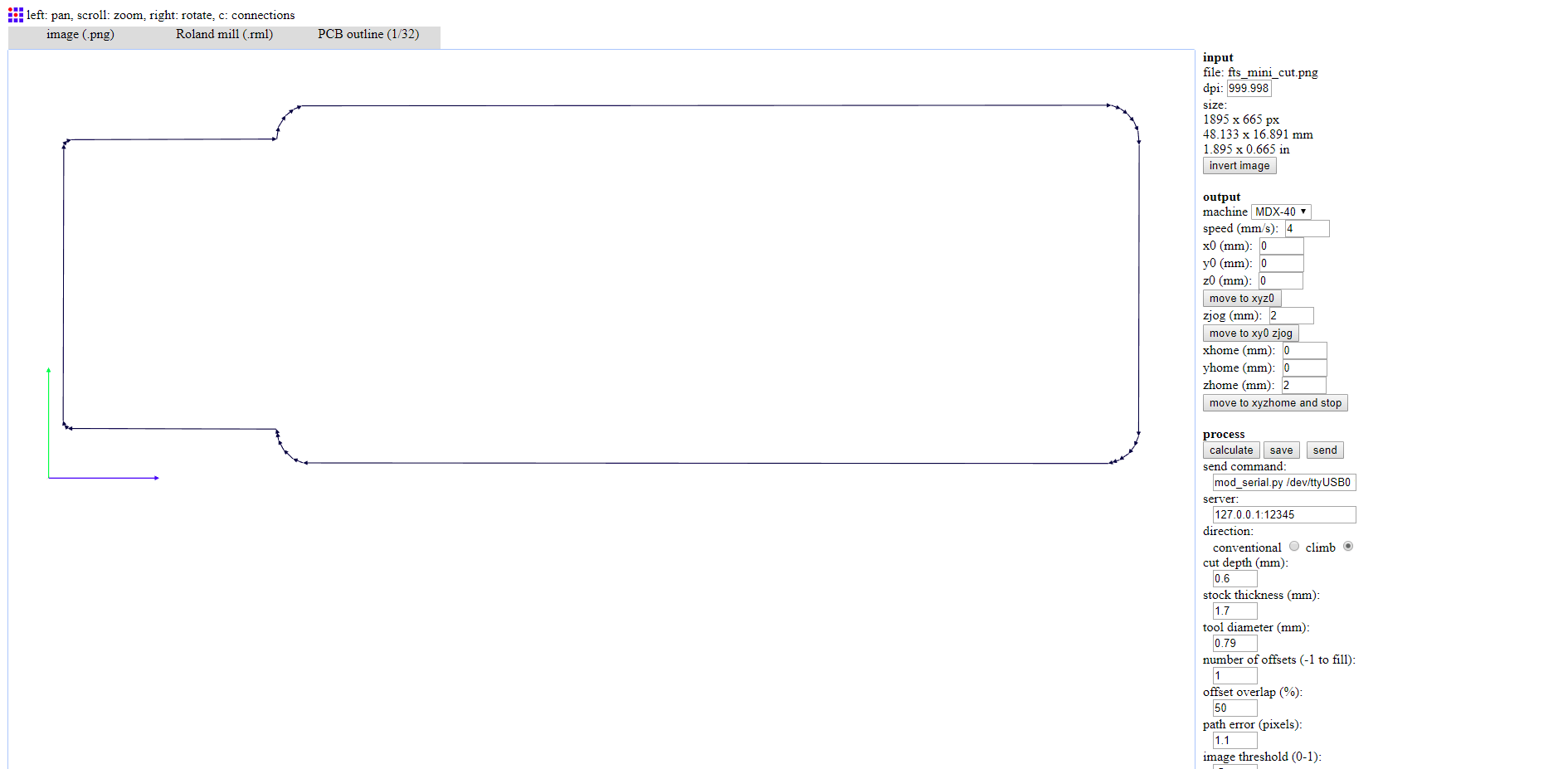

Fabmodules

I parsed the traces through fabmodules site, which converts png files among others to machine readable files among many other things.

- Traces

*Outline

Milling

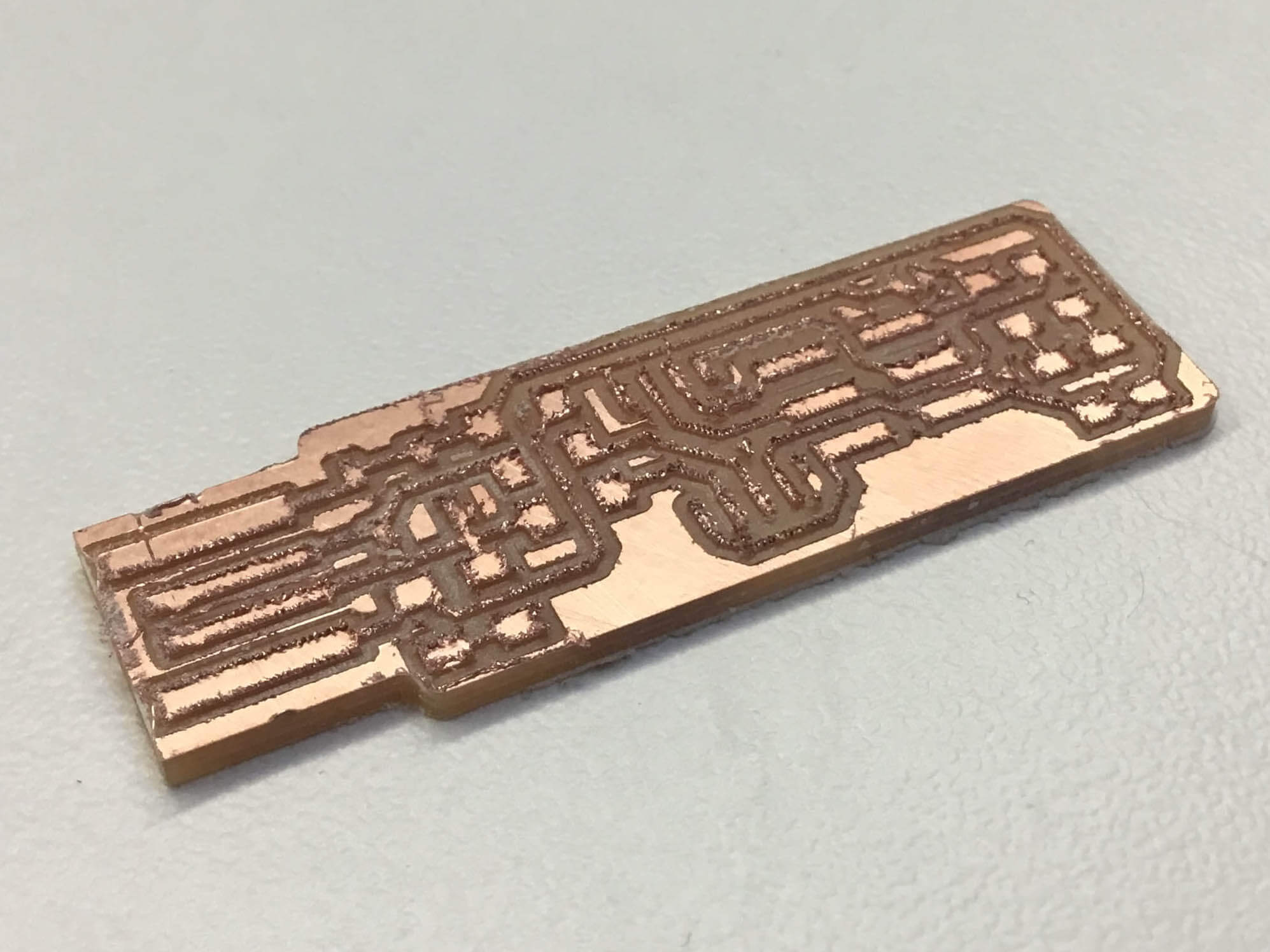

When I got the part out of the machine I was initially quite disappointed that it didn't look great immediately, but obviously of course not.

Clearly some work was in order, I could have got the tool to mill the excess copper from the board, but it'll just degrade the cutting tool, and ultimately just take a lot longer.

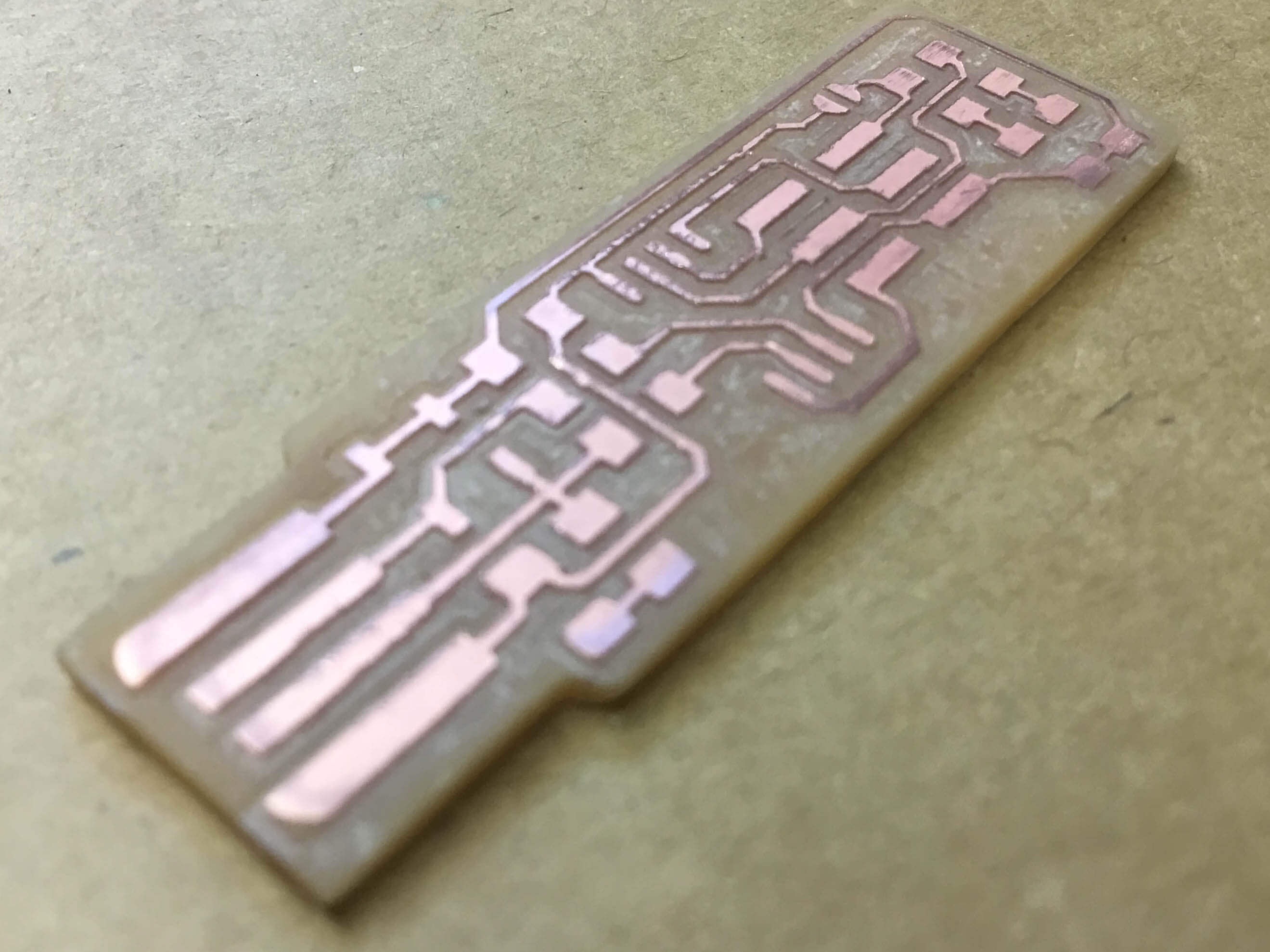

Sanding

After some sanding and scalpling the board was looking nice and clean.

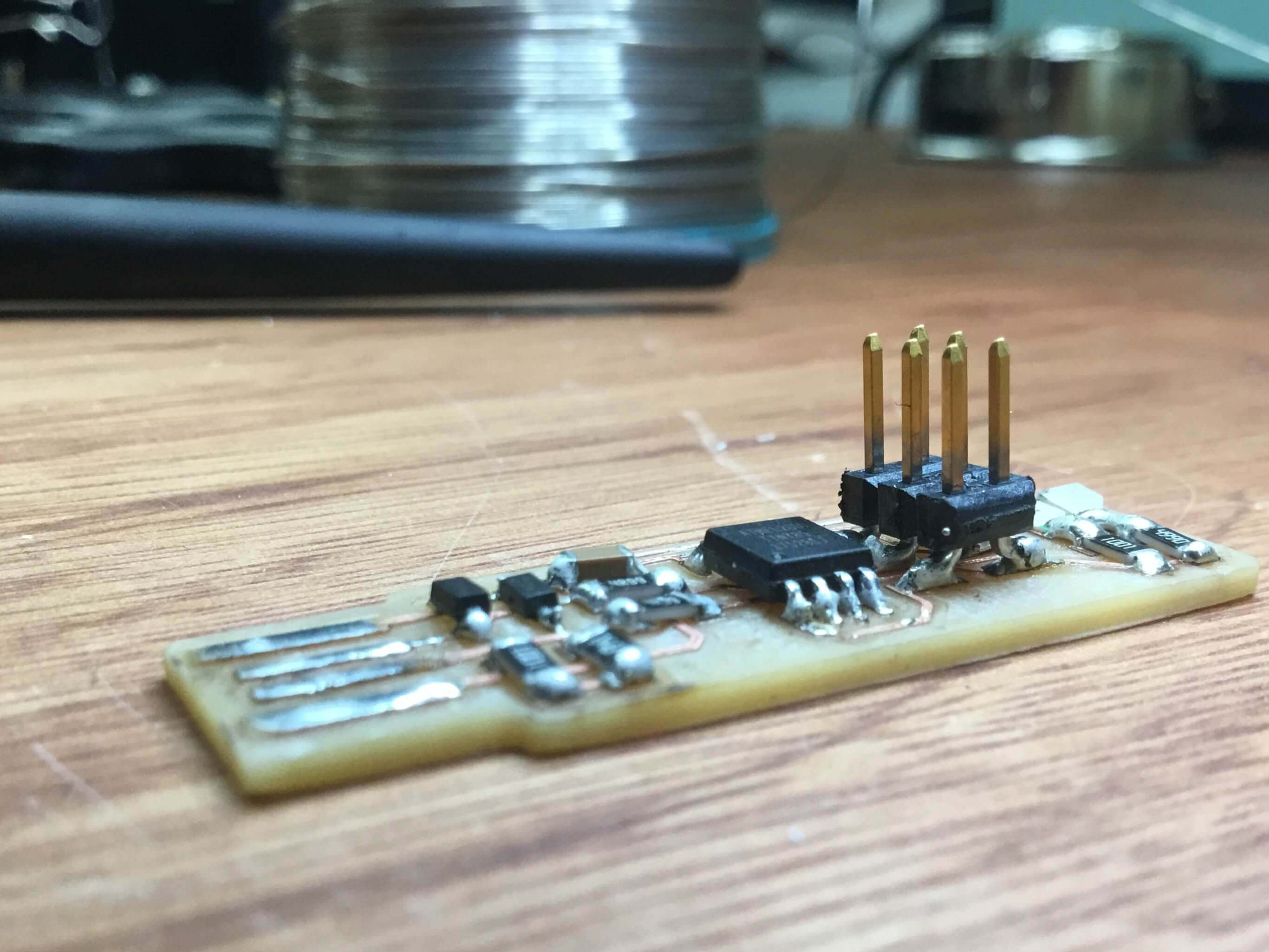

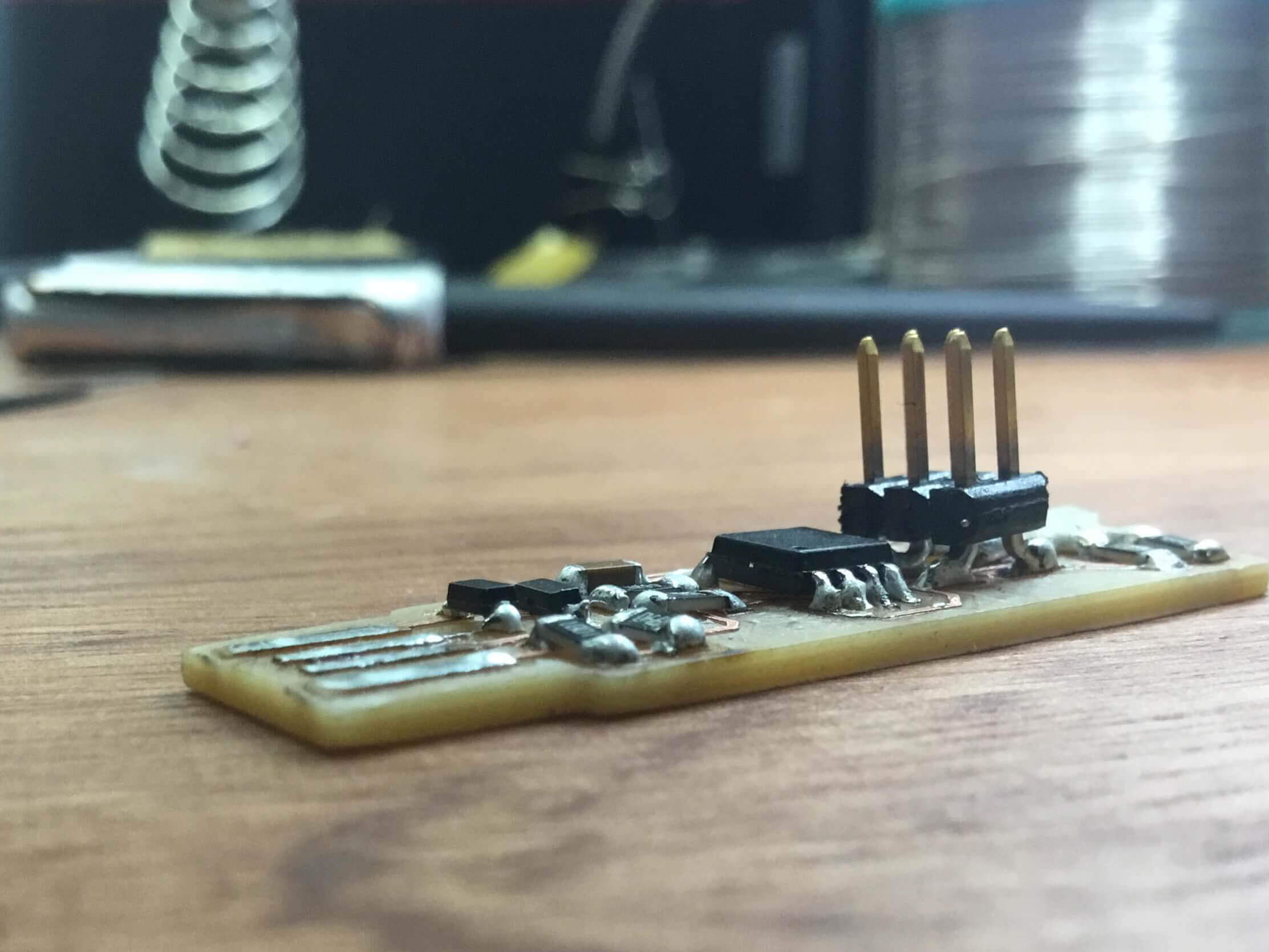

Soldering

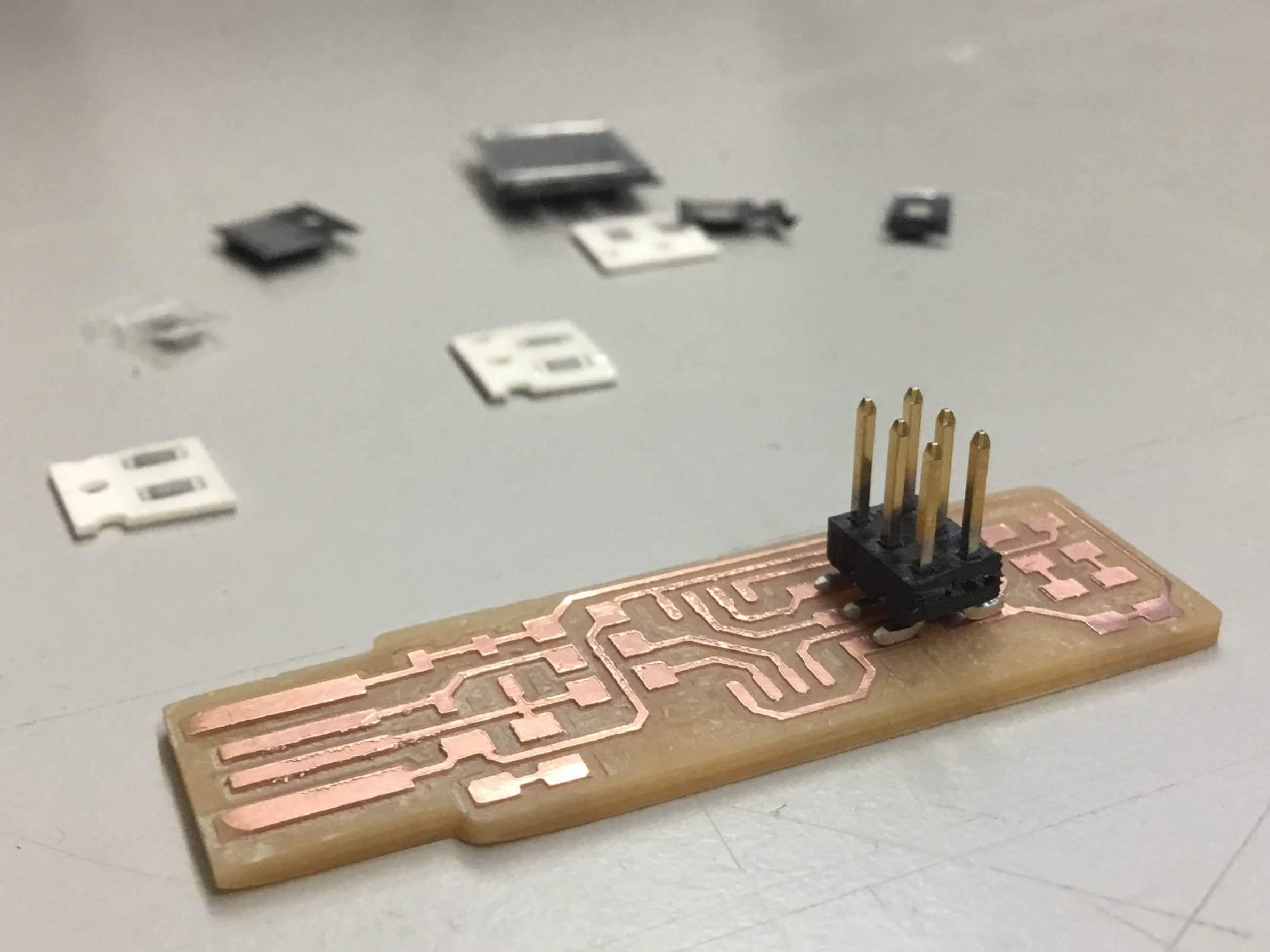

It was then onto soldering, I've been doing quite a lot of de-soldering for the purpose of scavenging parts for potential future use. This has also served as rather good practice for using a soldering iron.

I collected all my components together and got the schematic up infront of me.

I then soldered all the parts, and added solder to the pads

I will next need to test all of the connections with a multi-meter to check that I didn't make any mistakes. This'll also be important for making sure I got the LEDs the correct way around.

Programming

The next step will be to program the board such that it can function and do things.